Single Cell Protein Production Process

From one cell to a cluster

Starting off this week with a daunting joke…

The previous newsletter covered different types of microorganisms used in Single Cell Protein (SCP) production and their preferred substrate. This newsletter will illustrate how a few cells are grown into a bulk of dried cells.

Quick Recap

There are a few groups of microbial species that serve as base for SCP production:

Microalgae, Fungi (including yeast), Bacteria, Protists

These microbial species can grow on the following substrates (i.e. food input):

High-energy resources: gas oil, natural gas, ethanol, methanol, n-alkanes and acetic acid

Renewable plant resources: starch, sugar and cellulose

Various wastes: sulfite waste liquor, molasses, whey, milk and fruit waste

Carbon dioxide

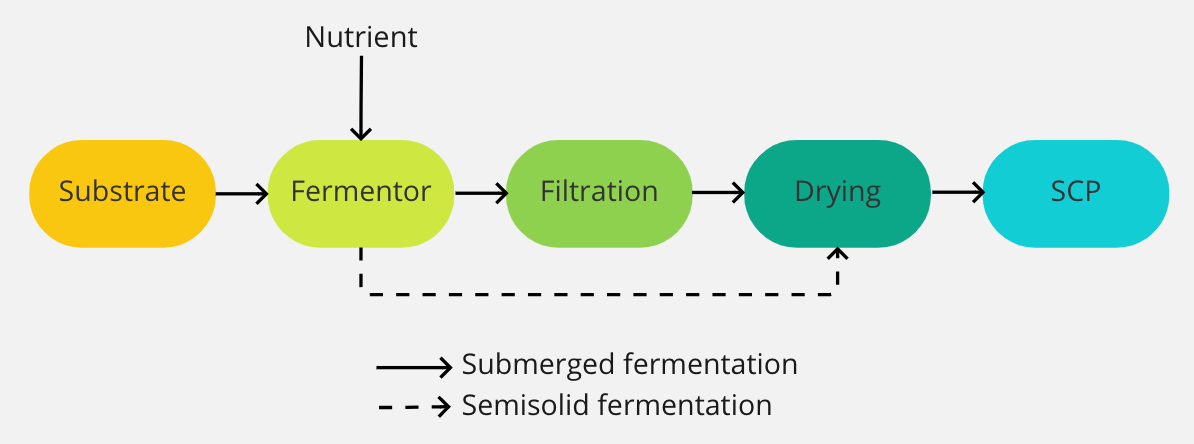

Simple Outline of SCP Production Process

Microorganisms + substrate >> Fermentation >> Filtration and Separation >> Purification and Processing >> Drying >> SCP

Selection of Microorganisms & Substrate

Cell selection is a meticulous process. The higher the yield (i.e. biomass produced per unit time), the more attractive the type of cell.

Preferred characteristics of a cell:

Tolerance against heat shocks. Cell’s ability to produce heat shock proteins as part of stress tolerance depends on its lipid composition. This reduces cooling needs and cuts cost.

Minimized production of RNA. Higher output produces more RNA in cells. RNA is an anti-nutritional factor and can inhibit growth.

Tolerance of a wide range of pH.

As the largest single cost factor (45-75% total production cost), good quality substrates in large quantities are hard to come by. Proper carbon to nitrogen ratio (generally 10:1 depending on species) needs to be thoroughly maintained in the substrate. To manage cost, the following formula can be used to assess cost effectiveness:

Biomass yield coefficient = the total weight of newly produced cells per unit of consumed substrate

i.e. a slower growing cell requires more substrate

Growth in Substrate

Once optimal cells are determined, they multiply on suitable substrates. This is known as the technical cultivation process. Upon reaching biomass thresholds, cells undergo screening and separation processes. Suitable production strains are collected and are subsequently optimized via selection, mutation or other genetic protocols. All these preparations ensure a pure and healthy culture of the selected cell for growth in a fermentor.

Some articles use bioreactor and fermentor interchangeably. To clarify, a bioreactor is the vessel that facilitates various types of biochemical reactions whereas the fermentor is the vessel that facilitates fermentation. Hence, a fermentor is a type of bioreactor.

Fermentation

The mass multiplication of cells occurs during the fermentation step. There are two common types of fermentation:

Submerged fermentation

Semisolid state fermentation

Submerged Fermentation

The substrate is kept in a liquid containing nutrients essential for growth. Biomass is harvested continuously. Yeast and bacteria are commonly recovered via centrifugation, while filamentous fungi are collected via filtration.

Two critical operation criteria are to ensure sufficient aeration and cooling (heat generated during cultivation).

Semisolid Fermentation

Semisolid fermentation uses solid substrates and requires extensive substrate preparation. The cultivation process involves stirring and mixing of a multiphase system, transporting oxygen from gas bubbles through the liquid phase to the microorganisms, and transferring heat from liquid phase to the surroundings.

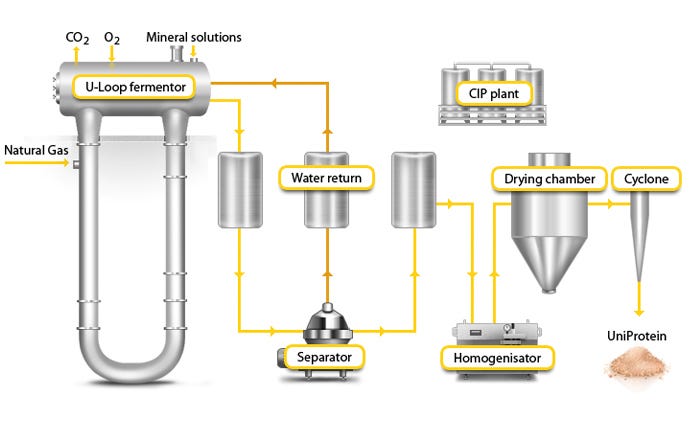

A U-loop fermenter is specially designed for mass and energy transportation for high gas utilization.

The fermentation process can also be further categorized based on the type of cells and their metabolism process.

We won’t go deep into the nitty-gritty of cell metabolic processes in this article. Though, if interested, here’s a great research paper that covers different type of metabolic processes in depth. Instead, we’d like to point out that companies leverage different type of bioreactors based on the specific metabolic processes and substrate preferences of a chosen cell.

Aerobic Bioreactor: KnipBio, Veramis, Arbiom & Menon

Anaerobic Bioreactor: White Dog Labs, Fluid Quip Technologies & ICM

Gas Bioreactor: Calysta, Unibio, String Bio, Kiverdi, NovoNutrients, Solar Foods, LanzaTech, White Dog Labs

Photosynthetic Bioreactor: BioProcess Algae & Pond Technologies

Open Cultivation Systems: iCell Sustainable Nutrition, Cellana

Upon completion of the fermentation process, biomass is further processed via purification, cell disruption, washing and protein extraction to provide high production rates with high yields.

Production Cost Considerations

SCP production costs can add up quickly. To scale SCP production, large scale fermenters are essential. High biomass production, high substrate usage, high oxygen transfer rates and respiration rates, result in increased metabolic heat production thus the need for an efficient cooling system.

Majority production cost stems from:

substrate costs - largest single cost factor. Factors considered include site, raw material production, process capacity of plant, substrate yield.

utilities - second largest cost component. Energy usage for air compression, cooling, sterilizing and drying.

capital load

product-specific variables

Conclusion

The future of SCP will be heavily dependent on the reduction of production costs and the improvement of fermentation quality and downstream processing. The increased integration of applied genetics with recombinant DNA technologies will accelerate yield improvement.

Up next, aquablurb will highlight SCP startups and current testing / commercialization progress.